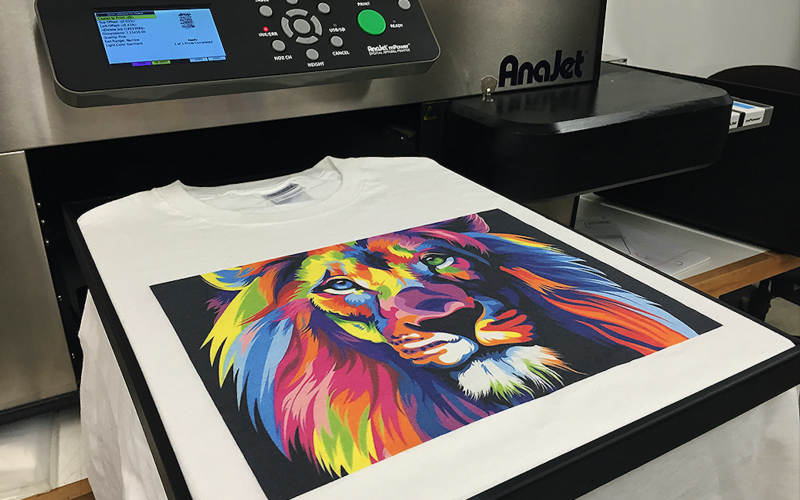

DTG printing is the best t-shirt printing technique being used. We provide DTG printing services in Dallas, let us discover the advantages and disadvantages of this printing method.

Advantages

- fast printing and applications

- guaranteed color output

- color gradients, gradient can be printed

- it is printed directly on the textile, which guarantees the permanence of the print

- unlimited color printing in high resolution, photographic quality

- printing is possible down to the smallest details, shading, color transitions

- can be printed on both light and dark textiles

- the printed surface is smooth and soft to the touch (when printing on white fabric)

- the print is very resistant to washing and UV radiation

- the price is independent of the number of colors

Disadvantages

- not worthwhile for larger volumes of approx. over 30 pieces (prefer screen printing)

- maximum print size up to A3 format (297x420mm)

- t-shirts should have a weight of at least 160 g/m2, for a guaranteed result we recommend 180 g/m

- cannot be applied to mixed textiles where artificial fibers predominate – fleece, polyester, etc.

- the minimum cotton content must be 80%.

- printing on dark fabric (other than white) requires a white underprint, the motif of the print takes on thickness

- cannot be printed on edges, seams. There must be a min. between the seam and the motif. 1 cm

About DTG (Direct To Garment) technology – direct digital printing

The graphic template is entered directly into the digital printer. The textile is pinned or threaded onto the mat and the printing program is started. The entire printing process is fast, accurate and precise.

This technology enables the printing of bape hoodie full color motifs (CMYK) including small details on textiles, while the print quality is very close to screen printing. Direct textile printing machines use white + the 4 primary colors of the CMYK color spectrum – cyan, magenta, yellow and black to create the desired colors. This is how the printer is able to create millions of color variations.

On the other hand, the color does not fully match pantone colors, the colors are less contrasting than, for example, with TRANSFER / FLEX / FLOCK technology. Fiber absorption affects color rendering.

Printing is possible on white, colored and black textiles, ideally made of 100% cotton (a small admixture of polyester in tested textiles is acceptable). For colored / black textiles, printing is more complicated. It is necessary to first underprint the motif in white, which is why it is also more expensive and the printed surface is less delicate than when printing on white fabric.

The printed surface is fine and soft to the touch, the textile is pleasant to wear (the print is directly in the fiber). The print is resistant to washing and UV radiation (if the care instructions are followed).

the printed motif does not have to be in curves (vectors), the option to print a .jpg image, photo, etc.

Maintenance recommendations: wash at 40°C from the reverse side, possibility of ironing over the motif from the reverse side

Do not use bleach, do not tumble dry.

print on cotton

print on polyester

piece printing 1 – 25 pieces

printing over 25 pieces

if you are in a big hurry (within 24 hours)

if you are in a hurry (within 72 hours)

if you are not in a hurry (within 10 days)

When to choose direct digital printing

When printing full-color motifs (photos), scanned materials, own creations.

Optimal printing on t-shirts, sweatshirts, canvas bags, and other cotton products.

For our customers, we print with this technology most often for the following reasons:

- quick gift

- from love

- Bachelor Party

- end of school year

- on water

- company logo

- family outfit

- own merch

- original pieces

Calculation for printing

To process a non-binding calculation, we need to know:

- type of textile (T-shirts, polo shirts, jackets, etc.)

- total number of textile pieces

- in the case of a custom textile, the composition of the material

- motif / picture / logo, if you don’t have one, then at least the number of colors

- for embroidery, always a preview of the embroidered motif

- approximate size and location of the motif on the textile

- special requirements (paper tags, textile labels, effect printing, individual packaging, etc.)

What will be the procedure?

- Create an order for textiles in the e-shop, attach an image and printing instructions in the product details. If you are not sure about the choice of textile, send the motif (picture) and textile requirements to the e-mail sales@dallasshirtprinting.com

- we will check the sent data and their suitability for printing or embroidery, in case of unsatisfactory documents we will inform you within hours. Standard communication takes place by e-mail (price offer, proofreading) – both the price offer and the proofreading must be confirmed. In urgent and specific cases where we need to clarify information or discuss technological options, we will contact you by phone

- based on the order, we will prepare a final price calculation and set an approximate delivery date (0-2 days)

- if the calculation is confirmed, a pre-print proofreading (preview) is prepared for approval – proofreading is prepared by a professional graphic artist for each order separately (0-2 days depending on complexity)

- after confirmation of the proofreading, the order goes into production and will be made according to the agreed delivery date (from 24 hours to 10 days according to the previous agreement)

- we will thoroughly wrap the order, seal it and hand it over to the courier for delivery, and you can look forward to the new textile

- special requirements (paper tags, textile labels, effect printing, individual packaging, etc.)